Circular motion vibrating screen - Light type 13

Purpose and use

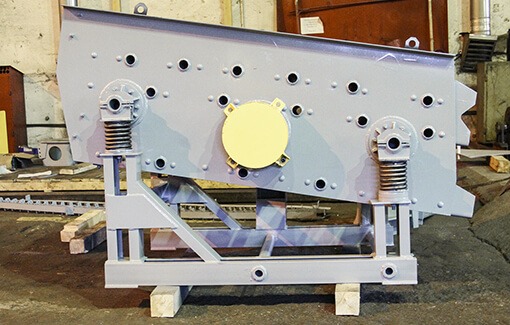

Circular motion vibrating screen Light type 13 is designed for the separation of bulk materials with a maximum feeding granularity 300 mm and with a bulk bulk mass of not more than 1.4 t/m3 during dewatering, desliming, and dry screening operations (with a surface moisture of not more than 5%). The equipment is used for work in enclosed premises at crushing, screening and concentrating enterprises in countries with a temperate climate. It is made in basic execution.

How screen works

The material from the feed chute enters the screen sieve. There is a fluctuation of the screen box. The material is transported to unloading and sifted through the sieve holes. The material that has passed through the openings of the upper sieve is fed to an average sieve where a similar operation takes place. The material that has passed through the openings of the lower sieve enters the lower sieve. The material that has passed through the holes in the bottom sieve enters the funnel for the undersize product. The oversize product from the sieve enters the discharge chute.

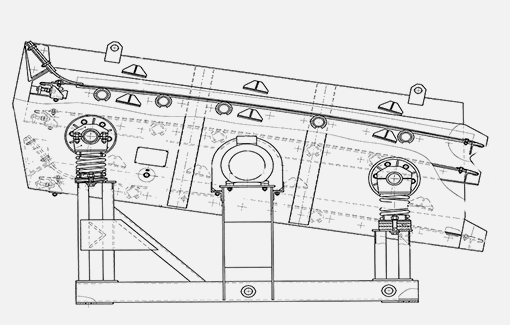

The screen box mounted obliquely at an angle (10-25 degrees) on the supports and under the action of the centrifugal force of inertia makes oscillatory movements.

Description

Parameters | Value |

Capacity, m3/h | depends on the type of material and screening conditions |

Screening surface size | |

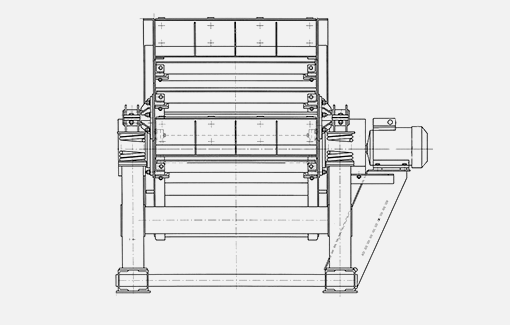

width, mm length, mm | 750 1750 |

Area of the screening surface of one tier, m2 | 1.2 |

Design type | Multideck screen (3 tiers) |

Screen cloth | |

wire mesh | size of sieve mesh are determined by customer |

Kinematic parameters | |

vibration amplitude of box, mm | 3-4 |

vibration frequency, Hz | 16 |

Overall dimension of shaking part | |

length, mm | 1920 |

width, mm | 1050 |

height, mm | 1295 |

Weight of shaking part, kg | 400 |

Deck inclination, ° | 10-25 |

Engine power, kW | 1.5 |

-510.jpeg)

.jpeg.image.resize-120_100_outside_any.e9876e37c5b4947a7a062b858b13f216.jpeg)