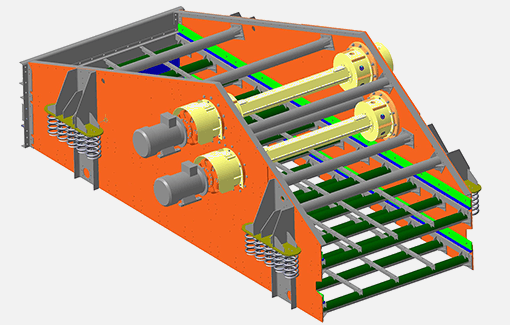

Vibrating screen - Type GIST-72 High frequency

Purpose and use

Circular motion self-balancing vibrating screen Type GIST-72 High frequency is designed for the separation of bulk materials with a bulk density of bulk cargo up to 1 t/m3 during operations:

- dry screening (with a surface moisture of a material of no more than 5% and a temperature of no more than 25°C with a separation margin of at least 13 mm);

- wet screening of ordinary coal;

- dehydration, desliming and washing the suspension from the products of their enrichment.

The size of the pieces of food at the screening of materials should not exceed 200 mm.

The equipment for screening can be used at the processing plants, mine sortorah and other enterprises, processing coal, anthracite and oil shale.

Description

Parameters | Value |

Screening surface size | |

width, mm length, mm | 6710 2410 |

Screening area | |

upper tier, m2 lower tier, m2 | 16.2 16.2 |

Effective area of screening surface | |

upper tier, m2 lower tier,m2 | 15.7 15.7 |

Design type | double deck screen |

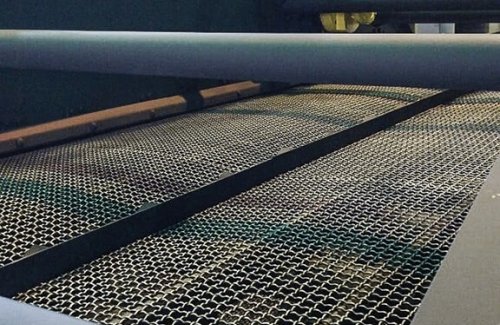

Screen cloth | |

|

determined by the customer |

Overall dimension of shaking part, mm | |

length, mm width, mm height, mm | 6820 3296 2656 |

Weight of shaking part without sieves, kg | 13000 |

Kinematic parameters | |

vibration frequency, sec-1 | 16.6 |

vibration amplitude, mm | 2-11.5 |

Deck inclination, ° | 0 |