Vibrating screen - Type GIST-72

Purpose and use

Circular motion self-balancing vibrating screen Type GIST-72 designed for the separation of bulk materials with a bulk density of bulk cargo up to 2.8 t/m3 during operations:

- dry screening (with a surface moisture of a material of no more than 5% and a temperature of no more than 25°C with a separation margin of at least 13 mm);

- wet screening of ordinary coal;

- dehydration, desliming and washing the suspension from the products of their enrichment.

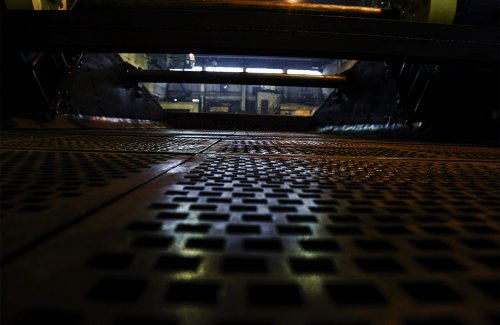

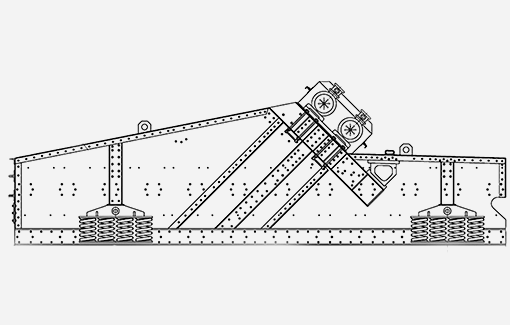

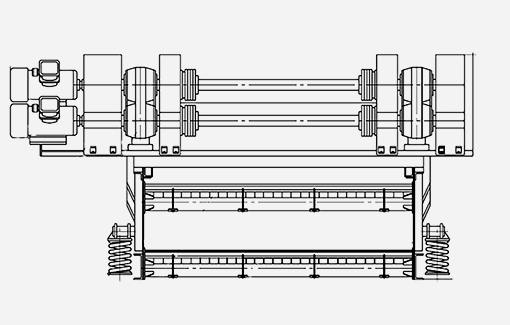

The screening machine is manufactured in supporting version with right or left drive arrangement. The equipment for screening includes: box; installation of vibrators; supports; installation of the upper and lower sieves; fencing rotating parts; vibrator motors; frame for installation and mounting of electric motors (optional); splash device (optional).

The screen used at the processing plants, mine sorting and other enterprises processing coal, anthracite and oil shale.

Description

Parameters | Value |

Capacity, m3/h | depends on the type of material and screening conditions |

Screening surface size | |

width, mm length, mm | 2500 6500 |

Screening area | |

upper tier, m2 lower tier, m2 | 16 16 |

Design type | double deck screen |

Screen cloth | |

| determined by customer |

Overall dimension of shaking part, mm | |

length, mm width, mm height, mm | 6810 3760 2390 |

Weight of shaking part without sieves, kg | 7200 |

Kinematic parameters | |

vibration frequency, sec-1 | 12,25 |

vibration amplitude, mm | 4,5-7,5 |

Performance indicators | |

maximum deck inclination, ° | 25 |

Lump size at the screening of materials with a bulk mass of bulk cargo | |

up to 1.4 t/m3, not more, mm | 300x300x600 |

over 1.4 t/m3, not more, mm | 120 |

Type of instalation | support type |