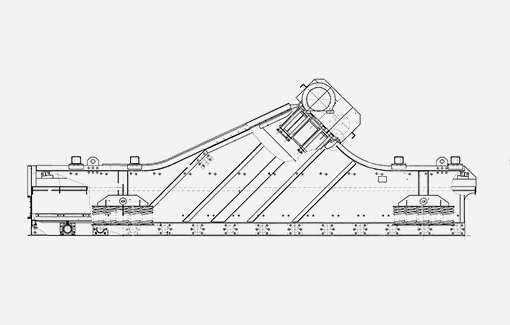

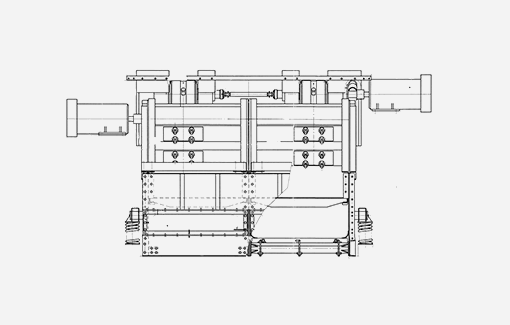

Vibrating screen - Type GISL-82

Purpose and use

Double deck self-balansing vibrating screen Type GISL-82 is designed to separate bulk materials with a bulk density of bulk cargo up to 1.4 t/m3 at deck inclination 0 - 15 ° during dewatering, slimeing operations, wet and dry (with a surface moisture of not more than 5 %) screening of coal, anthracite and combustible shale with a feed size of no more than 300x300x600 mm, as well as washing the suspension from their enrichment products.

Description

Parameters | Value |

Capacity, m3/h | depends on the type of material and screening conditions |

Screening surface size | |

width, mm lower tier length, mm upper tier length, mm | 3000 7580 8000 |

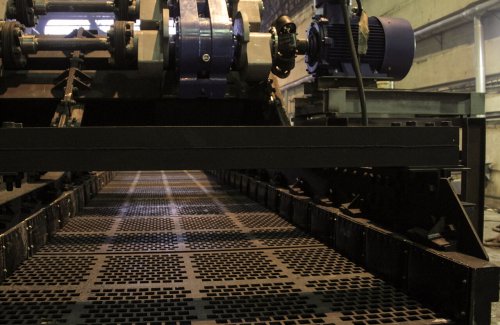

Area of one tier of the screening surface, m2 | 22.5-24.5 |

Effective area of the lower tier of the screening surface, m2 | 21.5 |

Design type | double deck screen |

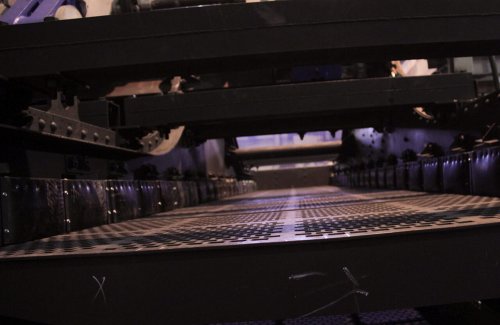

Screen cloth | |

Upper tier — punched-plate screen, mm | 10x10; 13x13;16x16;15x15; 20x20; 25x25; 30x30; 50;x50; 100x100 ⌀7; ⌀16; ⌀12: ⌀50 |

Lower tier— punched-plate screen, mm | 10x10; 13x13; 15x15; 20x20; 25x25; 30x30; 50;x50 ⌀7; ⌀12: ⌀50 |

Lower tier — wedge wire screen, mm | 0.5; 0.8; 1.0; 1.6; 2.0 |

Overall dimension of shaking part, mm | |

length, mm width, mm height, mm | 8200 4250 2700 |

Weight of shaking part without sieves, kg | 18500 |

Kinematic parameters | |

vibration frequency, sec-1 | 12.25 |

vibration amplitude, mm | 9 |

Drive motors | |

power, kWt | 74 (2х37) |

engine speed, rpm | 735 |

Performance indicators | |

deck inclination,° | 0-25 |

type of instalation |

|